[Case Study] Replacement of Oil Seal (Lip Seal)

Supports small lots and special groove dimensions during trial production! Selects the most suitable seal type for the usage conditions!

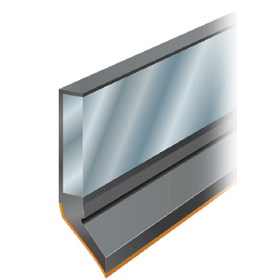

【Issues】 When installing the oil seal, the environment becomes harsher as the rotational speed increases, leading to problems such as short lifespan and high heat generation during high-speed motion. 【Improvements and Effects】 The metal ring lip seal and lip seal can be used at speeds exceeding 20 m/s. For applications with rotational speeds exceeding 3 MPa, we recommend using spring-loaded seals. Since the seal lip is primarily made of PTFE, it can be used in dry environments. There is no stick-slip, so there are no issues when restarting equipment or facilities after long periods of inactivity. Based on our experience and know-how, we will select the most suitable seal type for the operating conditions. *For more details, please refer to the PDF document or feel free to contact us.

- Company:シールテック 本社、大阪営業所

- Price:Other

![[Case Study] Replacement of Oil Seal (Lip Seal)](https://image.mono.ipros.com/public/product/image/259/2000695334/IPROS9489383045678345266.jpg?w=280&h=280)

![[Case Study] Replacement of Mechanical Seal (Lip Seal)](https://image.mono.ipros.com/public/product/image/3a2/2000695337/IPROS6154046294957248679.jpg?w=280&h=280)

![[Research Material] The Global Market for Medical Processing Seals](https://image.mono.ipros.com/public/product/image/bd8/2000845384/IPROS95297833101126153816.jpeg?w=280&h=280)